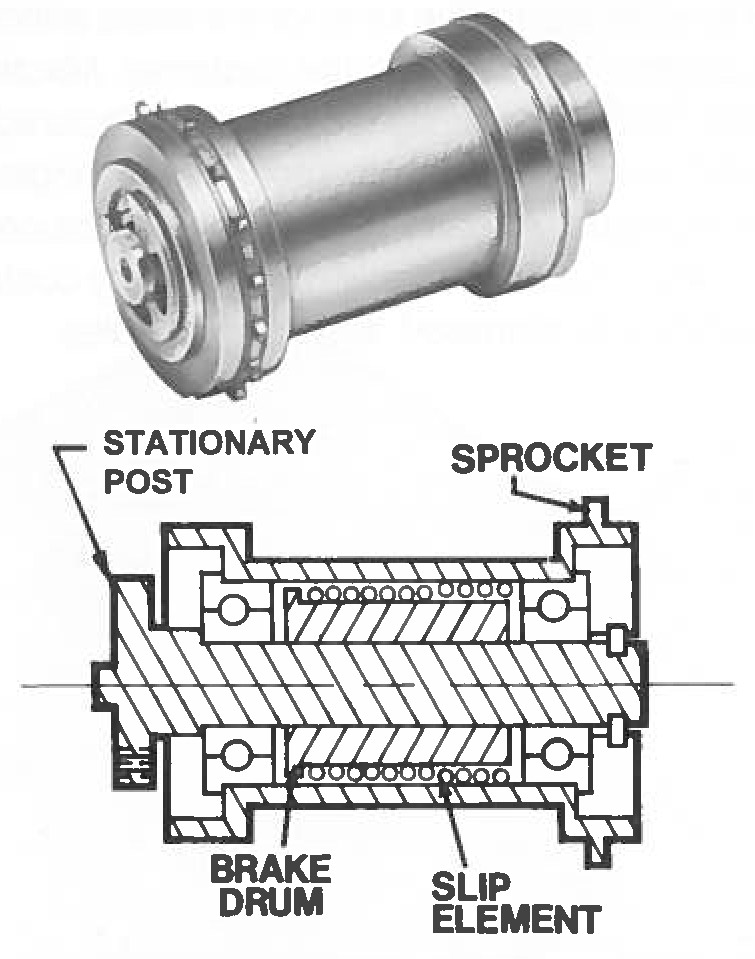

Film Tensioning Sprocket

Combines Drag Brake & Spring Back

A common problem in film handling is the creation of a slack film web when the drive is suddenly disconnected. Machine Components Corporation developed this sprocket/brake for a well-known film manufacturer to ensure a constant level of web tension independent of running speed, or deceleration during stopping.

The sprocket assembly is supported by a pair of integral ball bearings mounted on a stationary post. The internal drag brake provides constant tension to the film. The drag torque, which in turn imparts a constant tension level to the film, is produced by a wrap spring which couples the sprocket to the stationary post. Sudden decelerations, however, such as are caused by abrupt stopping of the drive, tend to produce a slack condition in the film web. In this case, the slack was found to be equivalent to about 5° of sprocket overtravel. The wrap spring was designed to produce about 50° of prewind prior to slip. Thus, whenever a sudden stop creates slack in the film, the prewound spring automatically drives the sprocket back to retension it.